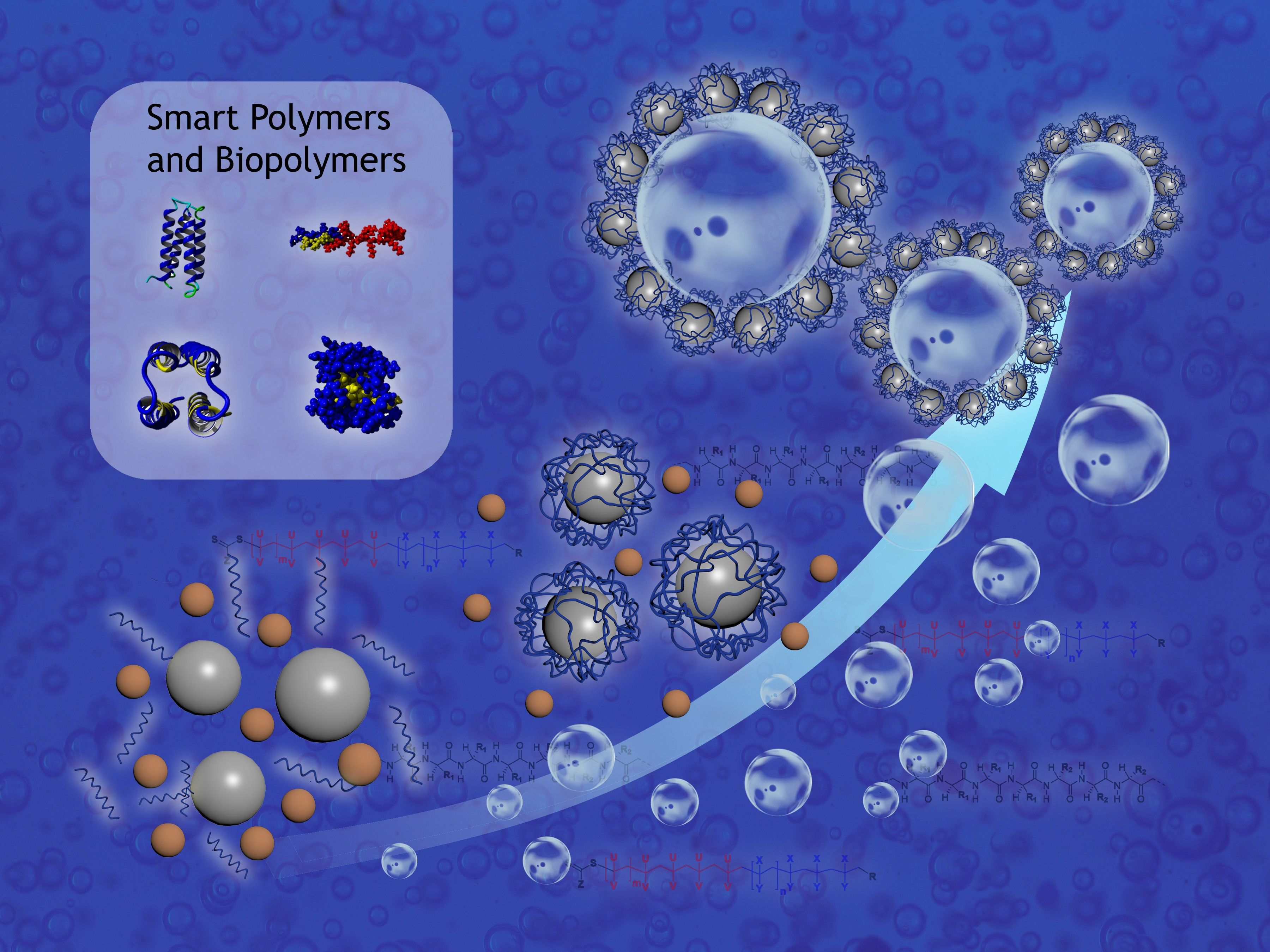

Program 3 - New engineered biopolymers and synthetic polymers

About Program 3

Program 3 aims to use the knowledge of how biomolecules and synthetic organic molecules and

polymers interact with minerals, coupled with novel synthesis concepts from chemistry and biochemistry to design mineral processing chemicals that give unrivalled performance in recovering valuable minerals, whilst also allowing the recovery of as much water as possible.

–

Application of polymers as collectors in minerals processing is relatively new. Polymers have traditionally been used in flotation to suppress recovery of certain minerals, while high molecular weight polyacrylamides have been the foundation of flocculation in solid-liquid separation. New approaches to the synthesis of more effective and cheaper polymers are now available for exploitation in minerals processing. These could lead to better concentrate grades, higher mineral recovery and new polymers to achieve improved water recovery.

Program 3 will use the knowledge of how polymers interact with minerals, coupled with novel synthesis concepts from chemistry and biochemistry, to design mineral processing chemicals that give unrivaled performance in recovering valuable minerals, whilst also allowing the recovery of as much water as possible. Polymers have been used extensively to stop unwanted minerals from being recovered and to manage the treatment of waste minerals. They have seldom been used for targeted recovery of the valuable minerals, and their use in water recovery from waste minerals has not seen a major advance in many years. Clever polymer chemistry, for both synthetic polymers and for biopolymers, will enable the production of the next generation of mineral processing chemicals that will perform better and be produced more cheaply than currently used chemicals in mining.

Program 3 consists of two sub-programs

The first sub-program will address major challenges in: i) improving selectivity of valuable mineral recovery; and ii) producing easily dewatered waste mineral streams through aggregation of fines. For both biopolymers and synthetic polymers, the work will focus on developing macromolecules for targeted adsorption, i.e. the inclusion of specific chemistries that will ensure the polymer sticks to the intended mineral, and not to others in the mixture. Coupled with this targeting will be an inherent design characteristic that will allow the polymer-coated mineral to present itself as hydrophobic as possible, ensuring optimum recovery – of minerals in the first instance, and of water in subsequent processing steps.

The second sub-program will take the novel chemistry of the polymers designed in the first sub-program, and they will be further exploited to develop stimuli responsive molecules for coating minerals. Stimuli, such as a change in pH, salt concentration, or temperature, or exposure to light, can result in altered surface properties for polymer-coated minerals, and therefore lead to altered process outcomes. Stimulus responsive polymers are employed routinely in areas such as biomaterials science, to control surface interactions of relevance for physiological processes. Minerals processing has the potential to benefit greatly from adopting the paradigm of stimulus responsive surfaces.

Professor Chun-Xia Zhao and Professor San H. Thang have shared some 2022 Program 3 highlights & future priorities

Based on the new phage display platform developed within the Centre, a library of biomolecules (monomers, dimers with different linkers) was designed and synthesised for specifically binding to different mineral particles. The binding peptides showed high binding affinity not only to mineral ions, but also to mineral particles. Therefore, adding the biomolecules into a mixture of mineral and waste particles led to aggregation and sedimentation of the mineral particles, but not the waste particles, achieving an extremely high separation factor (>1400).

Also, bio-inspired collectors based on cardanol, and α‑tocopherol (Vitamin E) as new reagents have been designed and synthesised in addition to the RAFT polymers to improve the froth flotation processes. All these collectors were found to have dual properties — foaming and selectivity for binding specific minerals offering the beneficiation of minerals using fewer reagents. Furthermore, a series of stimuli-responsive biomolecules and synthetic molecules have also been designed in responding to different stimuli including pH, temperature and the naturally occurring light. These new reagents can be purposely engineered as novel frothers or new collectors for aggregation and

flotation applications.

Research collaborations have led to these new reagents being used with different groups in the Centre. Different mineral systems have been trialled to test their performance. Some of the new molecules showed great potential in achieving improved performance in recovering valuable minerals or recovering more water. Moreover, these new biomolecules or bio-inspired polymer-based reagents are biodegradable and biocompatible, thus advancing our goal in delivering a

sustainable future for Australia’s minerals industry.

Some program 3 objectives for 2023 include:

- Achieve fundamental understanding of designed biomolecules with high selectivity and specificity using various techniques.

- Design biomolecules and synthetic polymers for improved aggregation, agglomeration and flotation of identified critical mineral systems (copper, lithium, rare earth, etc.).

- Apply the stimuli-responsive molecules as novel bio flocculants for clay particle flocculation.

- Investigate the adsorption and adsorbed layer characteristics of the new reagents on target and

model mineral surfaces. - Further extend the collaborations to incorporate novel reagents in aggregation, agglomeration and/or flotation across several more projects within the Centre.

- File Australian Provisional patents around the new reagents developed

Dig into all the details in our 2022 Annual Report, which can be found here.