Program 2 - Chemistry of novel hydrophobic and selective interactions

About Program 2

The overall objective of Program 2 is to support robust, fast, and efficient separation technologies

that are both selective and hydrophobic. This is achieved by studying the effect of hydrophobic

reagents on the surface properties and floatability of mineral particles.

–

For the last 100 years, high value minerals have been ground to a fine particle size and then separated by adsorbing reagents, known as collectors, onto the mineral surface to make the minerals hydrophobic, and attraced to bubble interfaces. New approaches are needed to exploit the full potential of hydrophobic interactions for i) separating coarser particles, ii) ultrafast and selective separations, and iii) separating almost all the liquid from the mineral particles at the end of the separation process.

Minerals of high value are rendered hydrophobic through the specific adsorption of reagents known as collectors. This has been the predominant methodology for 100 years, generally achieved through flotation. However, there is a need for new approaches to advance selectivity, and to properly exploit the full-potential of hydrophobic interactions in effecting i) coarser separations, ii) ultrafast and selective separations, and iii) a step change in solid-liquid separation. For example, our recent work shows that a 10 – 100-fold increase in the process intensification can be realised, so we know there exists a tremendous upside via our strategy to further exploit hydrophobic interactions.

Program 2 investigates the application of novel hydrophobic interactions utilising bubbles, emulsions, and foams, and the selective promotion of hydrophobicity at the mineral surface to support more robust, faster and more efficient separation technologies. This research seeks to extend the conventional notion of flotation into a far broader concept. Hydrophobic interactions are powerful, can be made selective, and potentially support very fast separations.

Program 2 consists of three sub-programs

The first is related to understanding how novel polymers (developed in Program 3) can be applied to selectively and efficiently recover both coarse and fine particles by froth flotation and agglomeration. Such advances will reduce the degree of fine grinding required via the introduction of early gangue rejection and reduce the loss of fine valuable product to tailings.

The second seeks to develop novel systems to deliver reagents to the surfaces of particles in order to control their hydrophobicity for collection via flotation, or the ultrafast agglomeration in Program 1. The novel delivery systems will reduce the amount of reagent required and enable faster recovery of valuable particles, resulting in reduced processing costs.

The third will develop understanding of how the use of the polymers developed in Program 3, and the novel delivery systems developed in our second sub-program can be applied to improving solid liquid separations, to end the practice of using tailings dams.

Professor George Franks & Associate Professor Liza Forbes shared some 2022 Program 2 highlights & future priorities

There was considerable progress in 2022 across all three sub-programs. Some of the highlights are given below.

2.1 Development of Novel Flotation Collectors

The objective of this sub-program is to develop novel reagents to enhance mineral surface

hydrophobicity. The key highlights in 2022 were:

- Improved understanding of adsorption of novel synthetic and biopolymers and

surfactants (from Program 3) to a range of surfaces, investigated through quartz crystal

microbalance measurements. - Development of stable oil-in-water emulsions for application in coarse particle recovery,

using conventional and novel surfactants (from Program 3). The emulsions have been

investigated through creaming rate, zeta potential and droplet size measurements

2.2 Development of Novel Delivery Systems

The objective of this sub-program is to examine new ways of introducing reagent chemistries into mineral processing systems. The key highlights in 2022 were:

- Investigations into stabilising both water-inoil and oil-in-water emulsions using starch,

cellulose, and fly ash. - Hydrophobic talc particles can be recovered with the use of a novel hydrophobic emulsion

binder. Initial investigation has commenced regarding pre-aggregating the particles

with a polymeric flocculant prior to binder agglomeration. - The benefits of placing collector on surfaces of bubbles (rather than mineral particles) to

enhance coarse particle hydrophobicity is being investigated. - A series of thermo-responsive polymers (PNIPAM-based) via the RAFT process have been screened for their ability to stabilise water-in-oil emulsions for binder agglomeration. The best candidate has been found to be effective in recovering hydrophobic

talc particles.

2.3 Hydrophobic Interactions in Dewatering

The objective of the third sub-program is to exploit mineral surface properties to improve suspension

dewatering. The key highlights of 2022 were:

- A team of researchers covering molecular dynamics and density functional analysis,

RAFT polymerisation, surface physics, and novel beneficiation has established a possible

way forward to improve the recovery and concentration of rare earth minerals. The

industry partner has signed on for a second study. - Agglomerating with oil-in-water emulsions and flocculating clay particles has been investigated.

Further processing via pelletisation was shown to improve the solid-liquid separation. - Chalcopyrite was found to selectively flocculate from quartz suspensions using conventional

polymers. The high molecular weight was demonstrated to be a key polymer property. The potential for conventional surfactant collectors to make those aggregates hydrophobic for selective recovery via froth flotation was demonstrated.

In addition, there has been strong collaboration with Program 3 researchers supporting all three sub-programs including:

- A range of bespoke RAFT polymers and surfactants have been synthesised to test

functionality and selectivity with model mineral systems in flocculation and flotation. - An initial set of novel peptide flotation collectors and depressants has been developed

and tested for metal ion and surface selectivity.

Some Program 2 objectives for 2023 include:

- Investigation of the spreading of oils on mineral surfaces via combinations of novel surfactants

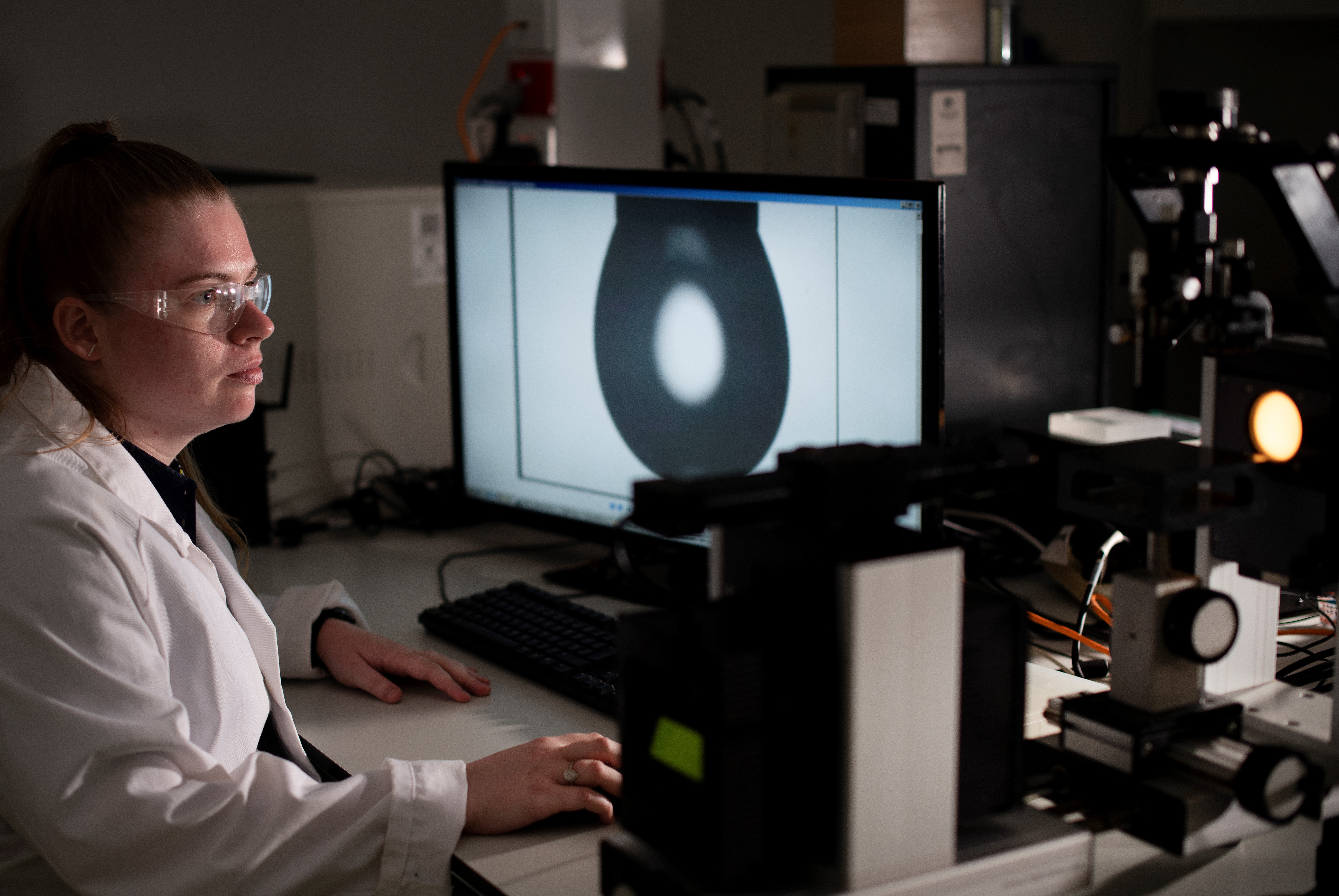

and polymers. - Measurement of contact angles of mineral surfaces when treated with emulsion droplets

stabilised by conventional and novel surfactants (from Program 3). - Investigation of the influence of pre-aggregating fine particles with polymer on the amount of hydrophobic binder required to agglomerate and recover those particles.

- Characterisation of the adsorption of novel polymers (from Program 3) on to mineral

surfaces. - Initial comparison of the influence of collector addition either through the solution phase

(conventional) or through the gas phase (novel). - Systematic investigation of the selective aggregation of chalcopyrite from quartz using

different polymers. - Investigation of the flotation of copper bearing minerals with conventional and novel polymers

sourced from Program 3. - Studies of bubbles attaching to oil-coated minerals using an oil-infused polymer layer as

a planar oil-water interface for initial studies of bubble collisions.

Dig into all the details in our 2022 Annual Report, which can be found here.