Theme 3 Solid-Liquid Separation

Theme Leaders: Professor George Franks and Professor Marta Krasowska

Research Theme 3 aims to improve the efficiency of solid-liquid separations in order to recycle more water during the process, reduce the amount of water and solids going to tailings waste, and to make those tailings safe to store by dry stacking, ultimately to eliminate the need for tailings dams.

The Centre aims to reduce water consumption in mineral processing, improve the safe storage of tailings, and enable the elimination of tailings dams. Understanding of how different reagents and delivery systems influence the size, density and water content of aggregates is crucial to designing efficient solid-liquid separation technologies. New chemical reagents including biopolymers and RAFT polymers are being developed for improved operation as we continue to learn more about how the polymer chemistry influences functionality and performance. This new chemistry is part of the solution to the problem.

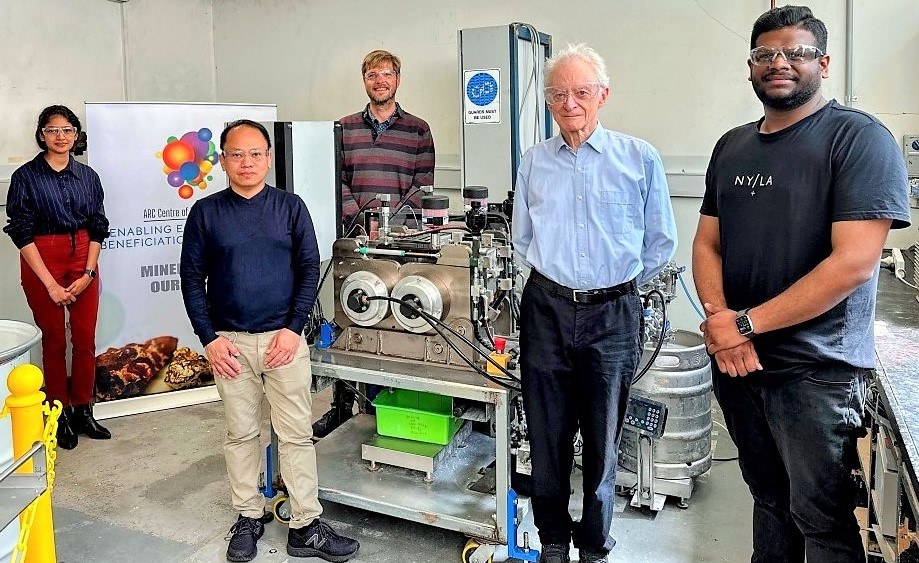

The other part of the solution is the development of new technologies to recover the water and make the tailings dry. The theme will develop the new equipment based on initial discoveries made during the first half of the Centre. These include further development, scale up and transfer to industry of the HPDR technology, and the new pelletisation apparatus.

Further work using novel reagent delivery systems to enable the bulk of the fine tailings to be recovered using froth flotation will be investigated. The Graviton offers the potential to separate the tailings into two portions, one which is coarser than 10 microns, which is easy to dewater, and the portion finer than 10 microns, which is responsible for liquefaction, and very difficult to dewater. This fine portion will have a relatively small volume and could be processed using new polymers directly in a thickener or by fast flotation. The concentrate would then be processed using an agglomeration or pelletisation technique ahead of the HPDR to produce dry stackable material.