New Tricks with Bio and Synthetic Polymers in Mineral Processing: As featured in the Centre’s 2021 Annual Report

To address the increasing complexity of mineralogy, new reagents in minerals processing are highly sought after, hence the need to develop materials for improving selectivity and functionality with some additional new tricks.

Fundamentally, particles lacking affinity with water can form through chemical adsorption and be recovered through hydrophobic interactions, (forces between particles and surfaces influenced by their “incompatibility” with water), to achieve adhesion with hydrophobic materials such as air bubbles. Next-generation reagents with better selectivity and functionality will revolutionise century-old mineral processing.

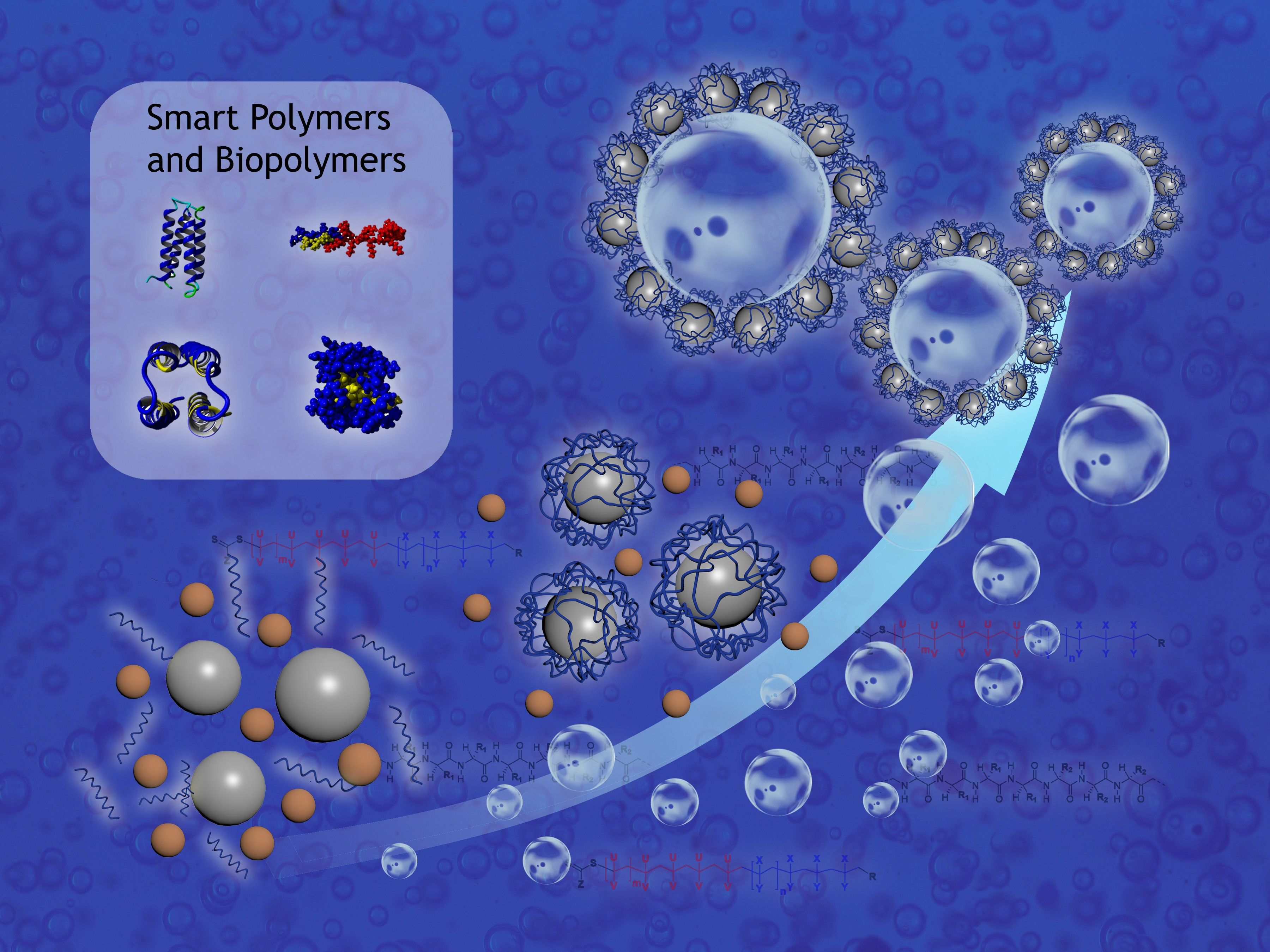

Polymers can be seen almost everywhere around us, as they are used widely in our everyday life. They can be classified as biopolymers and synthetic polymers. Synthetic polymers have been used in mineral processing (e.g. polyacrylamides) mainly as flocculants. Undoubtedly, developing biopolymers or synthetic polymers as collectors for mineral processing is going to be a new trick. Biomolecules, such as peptides or proteins are informational polymers made up of amino acids and are increasingly viewed as key building blocks to achieve specific functions owing to their biocompatibility, sustainability and ease of functionalisation, coupled with facile methods for their economic manufacture. Enabled by the diversity of the 20 naturally occurring amino acids, there is a large sequence and structural solution space for design.

Program 3 (in 2021) adopts a much greener and more sustainable approach to address the challenges in mineral processing and focuses on designing and producing new and sustainable biopolymers and synthetic polymers to improve selectivity, specificity and stimuli-responsive property. In this way valuable minerals can be efficiently recovered, and gangue (or worthless) minerals easily dewatered and removed. Furthermore, biopolymers and synthetic polymers can be designed to be smart so they can respond to external stimuli such as pH, temperature, salt concentration, magnetic force, or exposure to light. This will lead to altered surface properties of polymer-coated polymers and improve the process outcomes.

We will develop facile and quick platforms for screening good biopolymer and synthetic polymer candidates for selective binding to specific minerals and will design biomolecules and RAFT polymers for achieving hydrophobic flocs from hydrophilic clays. Based on the initial screening and molecular design, we will synthesise and characterise the designed biomolecules and RAFT polymers for their specific interaction with target model mineral surfaces. Adsorption studies will be conducted using different advanced tools to understand specific binding mechanisms. Also, interactions between the designed reagent and clays will be assessed. To further functionalise these polymers, stimuli-responsive biomolecules and RAFT polymers will be designed and synthesised for controlling froth stability.